Boat Bottom Painting Services – Protect Your Investment with Antifouling Bottom Paint

A well-maintained boat bottom is essential for performance, longevity, and fuel efficiency. At Top Notch Marine, we specialize in professional boat bottom painting to protect your vessel from marine growth, corrosion, barnacles and damage caused by prolonged water exposure. Whether you need a fresh coat of anti-fouling paint or a complete bottom refinishing, our expert team is ready to deliver top-tier service with superior results. We specialize in fiberglass and aluminum boat bottom painting in central Florida. We specialize in boats up to 30 feet and pontoon boats as well.

Why Bottom Painting is Essential

Boats that spend extended time in the water accumulate barnacles, algae, and other marine growth, which can slow you down and damage your hull. Bottom painting helps by:

- Preventing Marine Growth: Anti-fouling paint reduces drag and buildup.

- Improving Fuel Efficiency: A clean bottom means better mileage and performance.

- Extending Hull Life: Protects fiberglass, aluminum and metal surfaces from water damage and corrosion.

- Enhancing Resale Value: A well-maintained bottom signals proper boat care.

Our Boat Bottom Painting Process

Inspection & Preparation:

- Assess hull condition for blisters, cracks, or previous coatings.

- Pressure wash and remove old loose paint (if necessary) through pressure washing, sanding or media blasting.

Surface Priming:

- Apply a high-quality marine primer to ensure strong paint adhesion.

- Use epoxy barrier coats if needed for added hull protection.

Anti-Fouling Paint Application:

- Apply multiple coats of premium anti-fouling paint designed for your boating environment (saltwater, freshwater, or brackish).

- Choose from hard, ablative, or hybrid paints tailored to your needs.

Final Detailing & Launch Preparation:

- Inspect and touch up for flawless coverage.

- Ensure smooth water-ready finish for peak performance.

Outdrive and Lower Unit Protection:

- We offer cleaning, priming and painting of underwater running gear and metals such as lower units, outdrives and trim tabs. No need to hire divers to clean your boat bottom or running gear.

- We also install or replace sacrificial anodes, commonly referred to as zincs.

Why Choose Top Notch Marine?

- Expert Craftsmanship: 38 Years of experience in marine bottom painting.

- Premium Paint Options: We use only the best brands like Interlux, Pettit, and Sea Hawk.

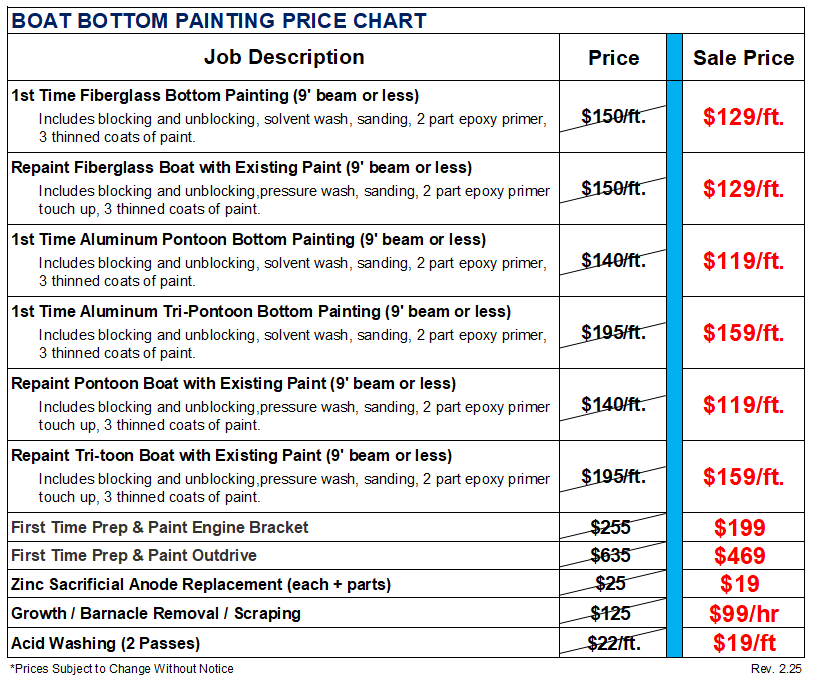

- Competitive Pricing & Fast Turnaround: Get high-quality work without long wait times.

- Convenient Florida Location: Serving Melbourne, Orlando and surrounding areas.

- Custom Solutions: Tailored to your boat type, usage, and water conditions.

Schedule Your Bottom Painting Today!

Don’t let marine growth slow you down! Protect your boat’s bottom and improve performance with our expert bottom painting services.

Call us today at 888-278-1991 or schedule an appointment online at www.topnotchmarine.com.

? Q&A for Boat Owners

Bottom paint, also called antifouling paint, is a specialized coating applied to the submerged hull of a boat to reduce marine growth (barnacles, algae, etc.). It protects your hull, improves speed and fuel efficiency, and minimizes damage from biofouling.

It depends on water conditions, boat usage, and paint type. Many boats benefit from a new coat every 1 to 3 years. Premium multi-season paints or harsh environments may require more frequent touch-ups.

Generally, two coats is standard, but for some ablative or copolymer paints, 2 to 3 coats might be ideal (or more), depending on the manufacturer’s instructions.

If the old paint is in good condition (not peeling, flaking, or incompatible), you can usually sand lightly and coat over it. But if it’s failing, or switching paint types (e.g. going to vinyl), full removal may be necessary.

Prep is key. Steps often include pressure washing, scraping away loose paint or growth, dewaxing, sanding, masking the waterline, applying a barrier or primer coat (if needed), then painting.

You should follow the paint manufacturer’s cure schedule. Many bottom paints require an overnight cure before you can splash. Failure to wait can cause the coating to detach once submerged.

Common types include ablative/self-polishing paints, hard (non-ablative) paints, and vinyl paints. Each has pros/cons for durability, performance, and how they wear in different water conditions.

For aluminum and other metals, you must choose paint formulations without cuprous oxide (which can cause galvanic corrosion). Some newer antifouling paints are copper-free and compatible with aluminum.

Estimate by measuring your hull’s underwater surface area. A common formula: Length × Beam × ~0.85 gives approximate square footage. Then consult the paint’s coverage rate per square foot.

Yes — by minimizing drag from barnacles, algae, and slime, a clean hull performs better, uses less fuel, and maintains better speed.

Key factors include water quality, fouling pressure, paint type, how often you run or clean the boat, and how well the paint was applied.

Professionals have the proper tools, skill, and experience to prep correctly (avoiding hull damage), select the right paint system, apply coatings correctly (thickness, cure times), and ensure long lasting protection.

Bottom paint removal and installation involves physical, chemical, and environmental hazards that

require proper precautions. Here are the key risks:

1. Toxic Dust and Fumes

Sanding, grinding, or blasting old antifouling paint releases fine dust containing heavy metals (like

copper and sometimes tin) and biocides, which can be harmful if inhaled or absorbed through the

skin.

In poorly ventilated spaces, solvents and paint fumes can cause respiratory irritation, dizziness, or

even more serious health issues without proper PPE.

2. Skin and Eye Irritation

Antifouling paints and strippers often contain harsh solvents and biocides. Direct contact can cause

burns, rashes, or eye damage if protective gear isn’t used.

3. Fire and Explosion Hazards

Many paint removers, thinners, and antifouling paints are highly flammable. Sparks from power tools or

poor ventilation in enclosed spaces (like boat sheds) can create serious fire risks.

4. Structural Hull Damage

Over-aggressive sanding or blasting can damage gelcoat or fiberglass, leading to water intrusion,

blistering, or costly repairs later.

Using incompatible primers or applying paint incorrectly can cause peeling and poor adhesion, which can

affect performance and protection.

5. Environmental Violations

Dust, chips, and runoff from bottom paint removal are regulated waste. Allowing these materials to fall

into the water or onto the ground can violate state and federal environmental laws, leading to

fines.

Marinas often require containment systems like tarps, vacuums, or tenting to keep debris out of the

environment.

6. Improper Application Risks

Applying paint in poor weather (too cold, humid, or wet) can cause premature failure, peeling, or uneven

curing.

Incorrect film thickness or timing between coats can also reduce antifouling effectiveness.

Why Hire a Pro

Professionals use HEPA-vacuum sanding systems, containment tents, proper PPE, and follow manufacturer specifications for paint systems. This ensures your hull is protected, your health is safeguarded, and your project complies with all environmental regulations.